The technology of PSA Nitrogen Generators produces nitrogen with a high purity of up to 99,9999% with 1.0 ppm residual oxygen covering flow rates from a few Nm3/hr to over 10,000 Nm3/hr. Like Membrane systems, these too are designed as free standing modular systems for easy integration into new or existing plant installations.

Description

The technology of PSA Nitrogen Generators produces nitrogen with a high purity of up to 99,9999% with 1.0 ppm residual oxygen covering flow rates from a few Nm3/hr to over 10,000 Nm3/hr. Like Membrane systems, these too are designed as free standing modular systems for easy integration into new or existing plant installations.

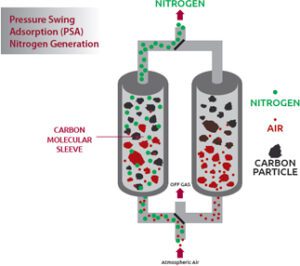

PSA technology is based on the adsorption principle: The nitrogen and oxygen molecules from the intake atmospheric air are separated by a carbon molecular sieve (CMS). The larger nitrogen molecules penetrate the system as they are not adsorbed by the activated carbon of the CMS. The nitrogen is then passed to the downstream nitrogen buffer tank system tank where the high purity nitrogen is ready to use.

These PSA Nitrogen Generators can be equipped as standard with touch control panels, modular expansion options and low maintenance valve technology.

How PSA Nitrogen Generation Works…

PSA Nitrogen Generation is carried out using the adsorptive properties of adsorptive media such as a Carbon Molecular Sieve (CMS) or Zeolite. Oxygen and other trace gasses are preferentially adsorbed onto the adsorptive media at varying portions depending on the system pressure while the nitrogen passes through due to its molecular structure being too large to penetrate the fine porosity of the adsorptive media.

The system uses two pressurised twin towers to contain the adsorptive media where the clean dry compressed air enters at the bottom of one of the towers – oxygen and trace gases are adsorbed and nitrogen passes through the adsorbent media bed into a buffer tank prior to the outlet, further filtration and onwards via the pipework distribution system to the process. After a predetermined time, dependant on the purity of nitrogen required, the tower switches to regenerative mode and flows the pressurised compressed air into the second tower (hence the term Pressure Swing…) where the process starts again. The first tower then depressurises and the adsorbed oxygen and other trace gases are released and exhausted to atmosphere.

What is adsorption? – In a gas application such as nitrogen generation this is the accumulation of molecules of oxygen and other trace gases to form a thin film on the surface of a specifically selected solid such as carbon or Zeolite by intermolecular forces – the adsorption process is reversible which facilitates the constant use of the system to generate nitrogen on a commercially viable scale.

A number of PSA (Pressure Swing Adsorption) twin tower units can be piped or manifolded together into a larger unit to enable high flow capabilities.